The following are questions that we end up asking ourselves;

- “How can I select a beginner or professional cut throat razor?”

- “How come the cut throat razor is pricier than others, even though it looks the same?”

- “How are the grind or point types going to function differently?”

This article will help you understand the important parts of a cut throat razor, and further teach you how to become a genius when choosing the best type of razor.

What is a traditional straight Cut Throat razor?

A cut throat razor basically has one straight blade that is fastened to a handle with the use of a pin. The blade is folded into the handle (also known as scales) when it isn’t being used. The best quality steel must be used for the blade, like silver and carbon steel.

One steel that razor manufactures hold in high regard is the Sheffield steel from England. It is important and ideal to maintain cut throat razors as often as possible. To do this you are required to wipe them dry immediately after use and store them where dry can circulate through the blades and scales.

The fin or edge of the razor needs to be frequently stropped with the use of a leather strop belt. The purpose of stropping is to take out tiny burrs that are formed on the fin while shaving. Stropping also corrects the fin which can sometimes fold over moderately between shaves.

A razor that is of good quality and properly maintained will deliver a close, smooth and tug free shave for as long as 9 months at least before it requires honing. Just like shaving and stropping, honing is another skill you will need to learn under a couple of months.

What are the types of razor steel?

It doesn’t matter if you are trying to choose the type of scissors or razor blade to purchase, trying to understand the metal or steel used to manufacture these products can be very confusing.What you should know about cutting steel is;

1. The hardness of cutting steal is measured with the HRC (Rockwell) hardness.

2. The sharpness of the blade is determined by how hard the steel is.

3. The average HRC hardness of razor blades is between 55 HRC and 62 HRC.

4. The cost of the steel depends on how hard and high in quality it is.

The most commonly used steel for blades are; carbon steel and stainless steel. Carbon steel holds its edges for long but also takes longer to hone. And stainless steel tend to lose its edges a lot quicker but is more impervious to rust and corrosion.

Carbon steel is the most preferred type of steel for razor blades because poor quality manufacturers and suppliers always use stainless steel without the right type of hardening. This is like using a blunt butter knife to shave.

A high quality manufacturer can make use of either steel types to make premium razor blades. We need you to understand that your choices are not limited to one or the other. Just be able to tell the difference in quality.

What are the widths of razor blades?

Differentiating between razor blade widths can be figured out through its weight and how easy it is to manoeuvre around areas that are difficult to access like beneath your nose.

Razor blades are measured as a fraction of an inch.

3/8” and 4/8” razors are relatively very small but possess their own advantages. Because of how small they are, they can easily be used to access under your nose and upper lip. They give better feedback thus making is easy to know where exactly the razor is.

5/8” and 6/8” are referred to as normal. They make shaving quite easy and are light as well. These type of razors are the most common and are highly recommended for beginners.

7/8” and 8/8” are the biggest in size. Because of their extra weight there is less resistance by the hairs. This is regarded as an advantage because you will be able to get a good shave with a less sharp razor blade. Another advantage is that they have more surface area to hold lather, and so you don’t need to wipe them off often. But they can be more difficult to move around.

How to choose the best straight razor cross section (blade edge)

What we refer to as the secondary influencer of the total weight of the razor is the cross section of the blade. For example, a full wedge razor has more steel in the blade than a full hollow.

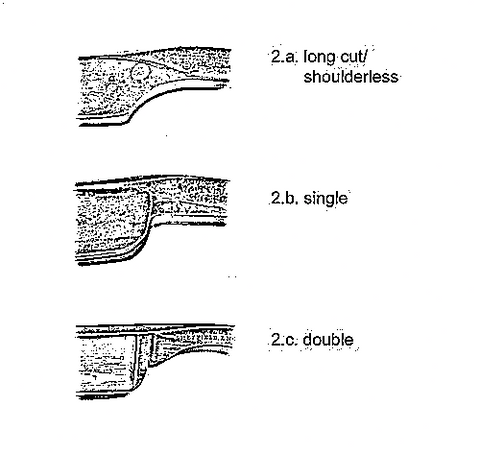

The diagram below shows the most common types of grinds and what they look like when you look at them from the point:

Singing hollow is also a type of grind that is an extremely hollow razor that got the name “singing” because of the sound it makes when shaving.

The basic purpose of a hollow grind is so that honing is made easier and the bevel of the razor should be aligned with the spine. What this means is that the rest of the steel available in a full wedge is far from the honing stone.

How to choose the best straight razor point type

The sharp and style point or tip of the razor blade us a combination of both aesthetic design and performance.

Round Points are the most common and highly recommended for beginners because there are no sharp points that can result in a cut with a wrong angled pass.

Flat/Square/Spike Points are valued for their ability to access areas that are difficult to reach. Areas like under the ear, under the nose and the likes. If an inexperienced shaver uses an incorrect angle the sharp point can cause a cut.

Barber’s Notch is a combination of a round point and a cut taken out. This is meant to provide safety of a round point and an additional flexibility to be able to have access to areas like around the nostrils and lips.

How to choose the best straight razor shoulder style

There are three ways in which the shoulder of a razor blade can be classified, and they are; shoulder-less, single shoulder or double shoulder. The shoulder is meant to stabilise the razor and is very important for razors with thinner grind.

The difference between the three classes of shoulder doesn’t affect their respective performances. The single or double shoulder are the most common and makes it easy for you to comfortably and confidently grip the razor.

How to choose the best straight razor blade finishing

The finishing on the blade is mainly on its appearance and has no effect whatsoever on how the razor performs or the steel’s quality. They are generally two categories of finished blades, but there are so many difference between both of them.

Satin Razor Blades: a satin finished razor blade looks more like a brushed steel made up of a number of fine scratches. The finer blocks will give a more satin type of finishing and the coarse ones will give a matt type of finishing. They are made to impart a specific kind of finishing.

Polished Razor Blades: after the blade has been polished to make it look as shiny as possible, you get a mirror polished type of finishing. A polished surface doesn’t get stained easily and is the best for straight razors that are mostly made out of carbon steel.

What is the history of cut throat razors?

Looking back at the civilisations of ancient Rome and Greece, iron blades with lengthy handles were used by men to develop the shape of the cut throat razor which was the only razor in use till the 19th century. As improvements came to the manufacture of steel so did cut throat razor blades that were surgically sharp and could be re-sharpened.

The more advancement in the razor blade technology completely changed shaving habits in the 20th century. As at 1900, shaving was either done by a local barber (one you trust to perfectly handle a cut throat razor), or done at home by yourself.

Well to do customer could own a set of seven cut throat razors, stamped or etched Sundays to Saturdays. With this, the user had access to a ready to shave razor every morning. And every week or twice a week the user will strop his razors, making sure the blades are sharp each day of the week.

As simple as the straight cut throat may be, doesn’t mean it is crude. The modern straight razor from the 1950s onwards now referred to as just razor is a distillation of design that has been evolving since the 1600s.

Razors got to the height of their designs in the 1930s or thereabout. As of this time, the blades were made out of the best steel available. They couldn’t be sharpened any further.

Tags

Blog posts